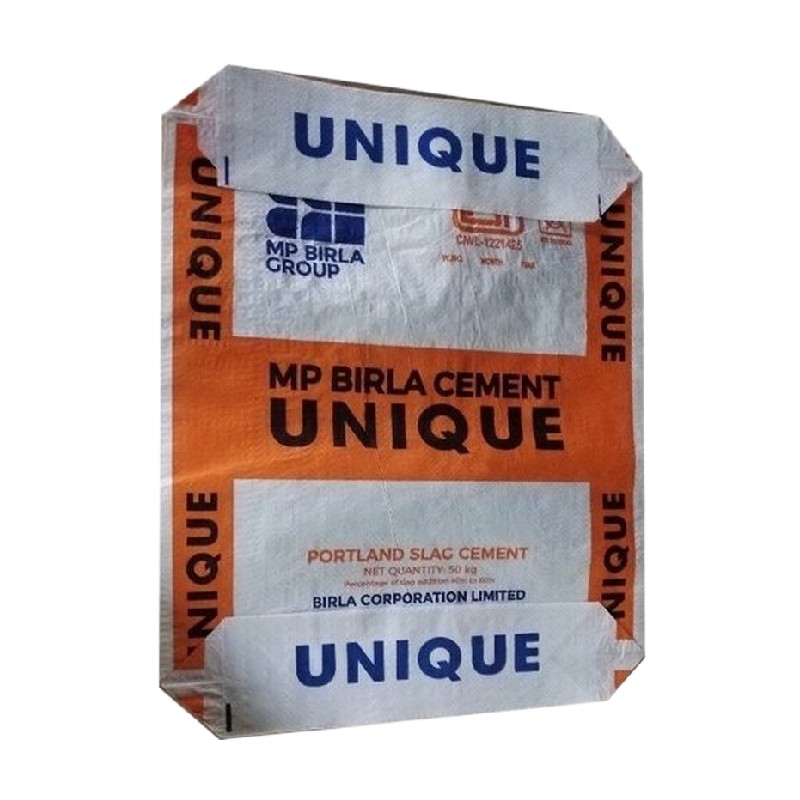

| Product | Customized Printing Laminated PP Woven Block Bottom Valve Sack Inner Valve |

| Material | PP woven Laminated |

| Color | With various colors or as per customer’s requirements |

| Printing | Max 4 colors in each side; Offset Printing |

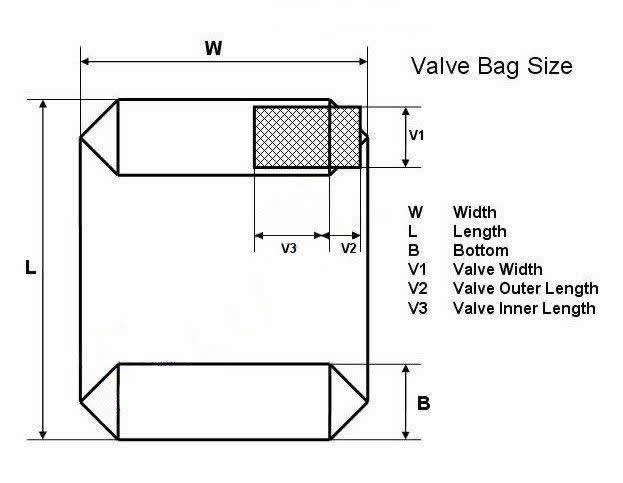

| Width | 350-600mm |

| Length | As per customer’s requirements |

| GSM | 80gsm- 150gsm |

| TOP | Inner Valve Mouth |

| BOTTOM | Square, hot sealed, stronger impact resistance, fine workmanship, professional protection to prevent leakage |

| Air Permeability | 100-120 Nm/hr or As per customer’s requirements |

| Feature | Moisture proof |

| Application | Chemical products, cement, putty, gypsum, carbon powder, fertilizer, powdered and granular goods,plastic resins and construction material, etc |

| Description | Woven polypropylene bag outer lamination with film to protect moisture and with self closing valve |

| Packaging | 4000-8000pcs/pallet, or as customers’ requirements |

| MOQ | 100000 bag |

| Production Capability | 60000000 bags/Month |

| Delivery Time | The first container within 30 days after order confirmation , the later as per customer’s requirements |

| Payment Terms |

T/T 30% in advance, T/T the balance before delivery |

The block bottom with valve – Ad*Star bag is characterized mainly by its high resistance to breaks, falls and friction. It is a strong and waterproof bag used for packaging different products from different industries.

It consists of a block bottom facilitating the palletization. This valve bag has an automatic closure, which allows it to escape at all seams. The laminated bag or block-bottomed BOPP bag offers an astonishing visual through the impression of each of its sides.

This range of bags can be declined to infinity according to the dimensions, the resistance or the choice of printing. The manufacturing process is very rigorous and requires frequent quality checks. Available in many standard formats, it can also be produced according to precise specifications according to the specific needs of our customers.

Example of use: cement bag, plaster bag, calcium carbonate (CaCO3) bag, various raw materials, etc.

Promote your brand by personalizing your bag.

Contact our specialists for advice or a personalized quote.

Resistance

PP woven polypropylene bags or laminated bags offer high resistance to breakages and drops. They also offer better moisture resistance than kraft paper bags. In addition, we offer an anti-UV treatment for bags exposed or stored in the sun.

Printability

Two printing possibilities are offered to customers. Direct printing on the laminated bag or by adding a layer of BOPP printed inside, to protect your visuals, while offering excellent print quality.

The main feature of this product is that it is possible to have an impression on each of its sides.

Dimensional stability

A wide and varied range with different well mastered widths, our processes are adapted to produce the desired widths.

Q1:Are you the factory or trading company?

A:Our factory was founded in 2005.We are family business, and our boss have more than 34 years producing experience. We supply cement bag for China Resources for 10 years, which is one of largest cement company in China.

Our factory comprise of :

Two Starlinger auto bag making machines(Starlinger Ad Star*Kon AX+)

Two Highspeed Tapelines

One Hundred and Fifty-Six Loom machines

Three Lamination machines

Seven Printing machines

Q2:What kinds of product can you provide?

A:Our main products are block bottom valve bags and Ordinary PP woven bag. We are professional manufacturer for cement bag, building material bag and chemical material bag. Especially for block bottom valve bags, our company has introduced two latest automatic bag making machines from Austria Starlinger company.

Q3:How can I get a quote?

A:You can contact me on the bottom of this page, and we need to know size, material, quantity, gram weight, printing, closure and other requirements you prefer to figure out an exact quote.

Q4:Are you willing to provide the samples?

We are happy to provide the samples to you. If sample is in stock, free sample and free express fee.

Q5:what is the payment term and delivery time?

Usually the payment term is: T/T 30% in advance, T/T the balance Before Delivery.

the delivery time is: within 25-30days for one 20ft container or 40HQ container for first time delivery.